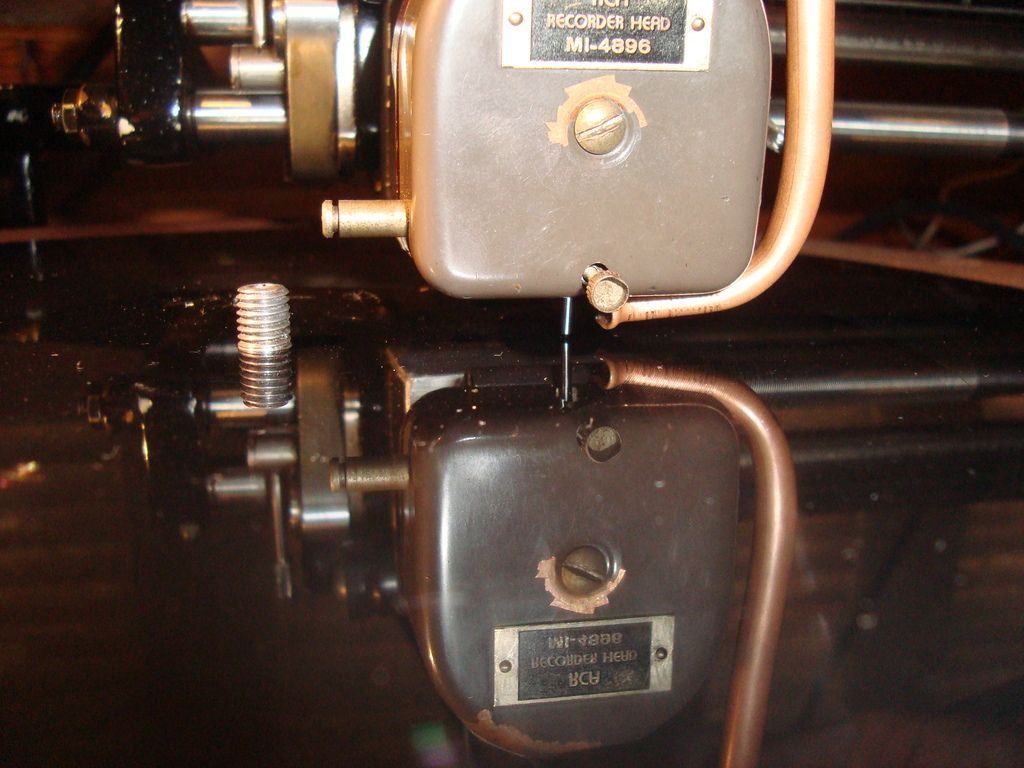

The result of my latest attempt at retrofitting the RCA head adaptor with a chip suction tube, has resulted in a suction tube chock full of chip. As in, packed full.

The hose upstream is clean. Rubber vacuum hose, that is. Not much is ending up in the chip jar, its all sticking in the first part of the tube. This happens just as much with lacquer as it does with PVC.

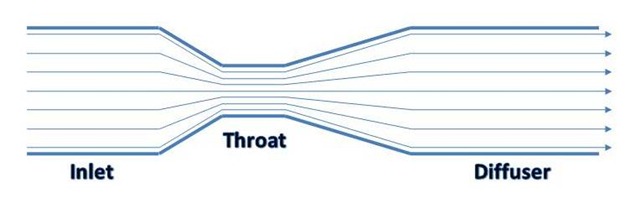

I am assuming that the problem is the vacuum pump. At the moment, it is a pretty strong vacuum cleaner, but strong as in airflow, airflow alone is not enough to properly draw the chip. What is needed is pressure, or the opposite of it, which is vacuum. When using a tiny tube to collect the chip, airflow is being restricted anyway. The problem with vacuum cleaners is that although they can provide a high volume suction, they do not have real vacuum capacity. Even if you restrict the airflow the vacuum does not see a significant increase. In a real vacuum pump, the idea is that reducing airflow increases the vacuum. Unless there is a safety system in place, a significant restriction in airflow would result in a significant increase in vacuum, which is what we need to really be able to pull this mess up. I have also tried an aquarium pump, which was a bit of a joke. I am now waiting for a real vacuum pump to arrive and will be trying the same system with it.

The vacuum cleaner was only able to produce - 160mbar of vacuum. I am hoping to do much better with the vacuum pump.

Anyone having any other pointers or ideas on this subject please feel free to contribute.