Powering a lathe, UK

Moderators: piaptk, tragwag, Steve E., Aussie0zborn

Powering a lathe, UK

I have the most noob question ever.

Basically, I'm in the UK, and I realise there's a whole bunch of problems regarding the motor speed of American gear. It's also very difficult to find any equipment over here. What I was thinking was that I could get a UK turntable, and attach an American overhead lathe to it, no problems.

This leads me to my question, which is this: does a lathe require independent power, or does it work like a dynamic microphone? Are there any obvious flaws in my plan (other than the fact I'm a noob)?

Basically, I'm in the UK, and I realise there's a whole bunch of problems regarding the motor speed of American gear. It's also very difficult to find any equipment over here. What I was thinking was that I could get a UK turntable, and attach an American overhead lathe to it, no problems.

This leads me to my question, which is this: does a lathe require independent power, or does it work like a dynamic microphone? Are there any obvious flaws in my plan (other than the fact I'm a noob)?

Re: Powering a lathe

Use a 240V to 12V power supply and hook that to a power inverter. The power inverter will give you 110V. A true or pure shine wave inverter will be best. Using a step down tranformer will not give you the 60 cycles that are need for the motor, Euro power only gives you 50.

for more info:

http://lathetrolls.com/viewtopic.php?f=4&t=4286&p=26291&hilit=inverter#p26291

for more info:

http://lathetrolls.com/viewtopic.php?f=4&t=4286&p=26291&hilit=inverter#p26291

Re: Powering a lathe, UK

I'm sorry, I think I have misphrased the question.

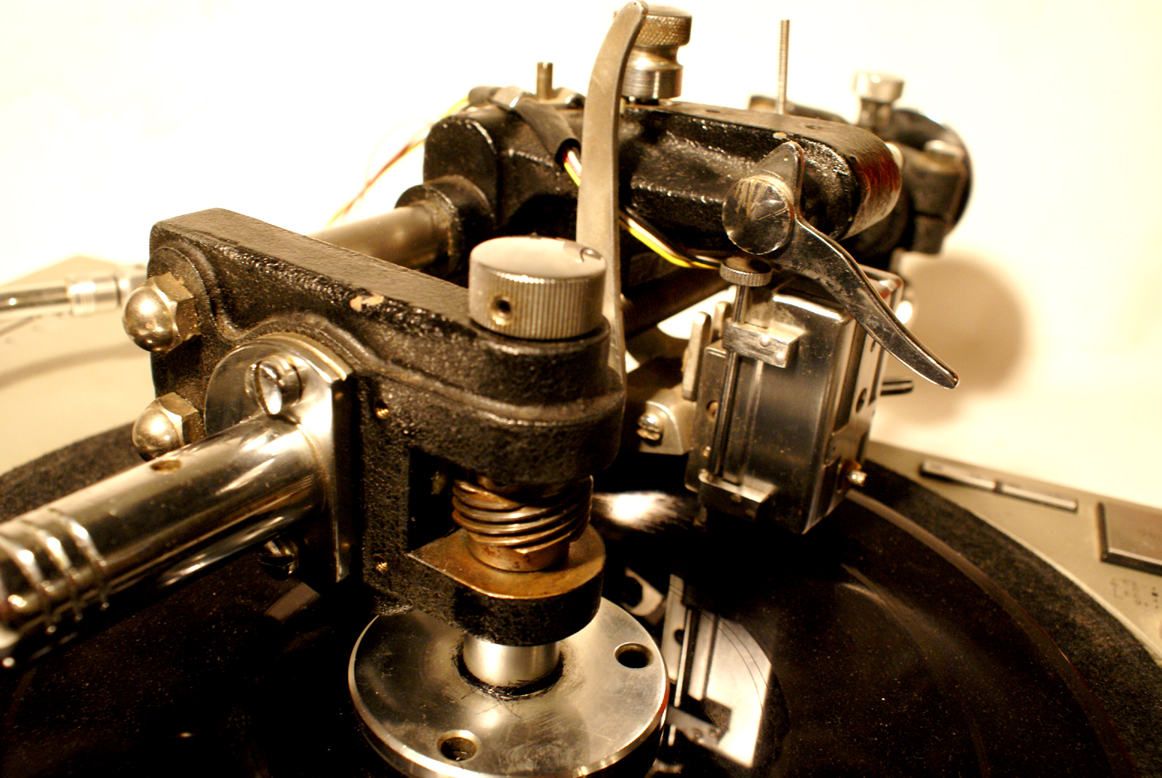

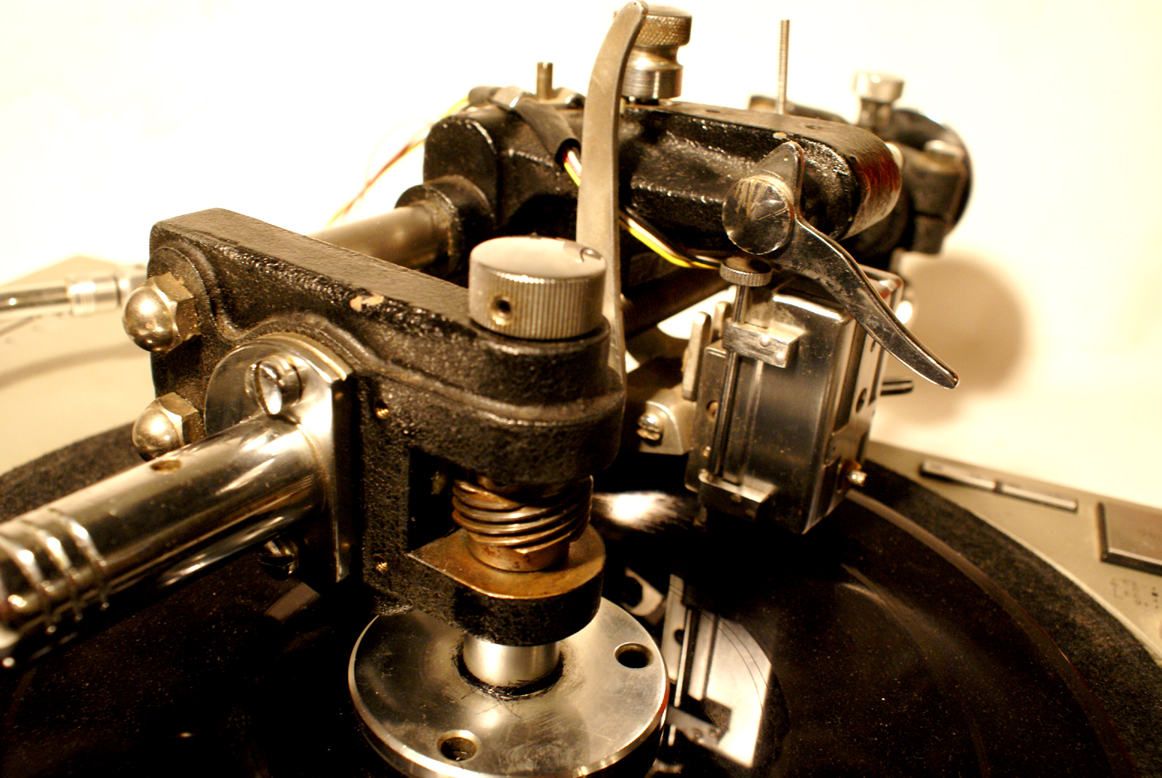

I am aware of the problems regarding the turntable element, but I was thinking I could just solve that by using a UK turntable in a setup like this:

My question was, does the lathe element require independent power? Would the cycles still be an issue?

I am aware of the problems regarding the turntable element, but I was thinking I could just solve that by using a UK turntable in a setup like this:

My question was, does the lathe element require independent power? Would the cycles still be an issue?

Re: Powering a lathe, UK

No, the lathe overhead works off of the turntable which requires a high torque to turn the overhead because of the extra weight and the down force of the cutter head while cutting. You'd need the turntable and an amp for the cutter head to cut in the above picture/scenario. Here's a picture of the screw inside the stem that runs off of the turntable which turns a cog that is connected to the overhead feedscrew. Your turntable has to power this mechanism and cut at the same time.

Re: Powering a lathe, UK

Hi,

As pictured, you are trying to use the turntable platter to power the overhead. This was done on the Presto 6N and with many other lathes of that era. I suspect that an SL1200 will have a very hard time performing that function due to its lack of torque. However, there is nothing to stop you from modifying the overhead mech and driving it with an external motor. In the case of the 6N style overhead, the gear reduction ratio was 8:1. So you can get a good idea of the speed required to drive the overhead directly. Note that there is no reason to have the platter synced to the overhead. It is also not nearly as critical to have good speed stability on the overhead as compared with the platter. In fact, once you de-couple the two functions, you can have variable pitch cutting with out changing feedscrews. Just change the overhead speed. You can use a DC motor with or without tach feedback to move the overhead. This makes it AC mains independent.

Mark

As pictured, you are trying to use the turntable platter to power the overhead. This was done on the Presto 6N and with many other lathes of that era. I suspect that an SL1200 will have a very hard time performing that function due to its lack of torque. However, there is nothing to stop you from modifying the overhead mech and driving it with an external motor. In the case of the 6N style overhead, the gear reduction ratio was 8:1. So you can get a good idea of the speed required to drive the overhead directly. Note that there is no reason to have the platter synced to the overhead. It is also not nearly as critical to have good speed stability on the overhead as compared with the platter. In fact, once you de-couple the two functions, you can have variable pitch cutting with out changing feedscrews. Just change the overhead speed. You can use a DC motor with or without tach feedback to move the overhead. This makes it AC mains independent.

Mark

Re: Powering a lathe, UK

Okay, I see.

I'd prefer to make as few modifications as possible (to limit the extent to which I can mess things up!)

Are there any transcription turntables I could get which would provide sufficient torque?

I'd prefer to make as few modifications as possible (to limit the extent to which I can mess things up!)

Are there any transcription turntables I could get which would provide sufficient torque?