Bobbin BBQ

Moderators: piaptk, tragwag, Steve E., Aussie0zborn

- Presto Repairs

- Posts: 81

- Joined: Tue Oct 28, 2014 8:02 pm

- Location: Melbourne - Australia

Bobbin BBQ

Today ive been dipping and baking coils for stock

I use an old bbq wiith a hood to bake my coils after dipping - it can do about 15 coils at a time

I use both of the end burners on low and bake for about an hour..

heres a photo of some coils that are about to be baked...

I use an old bbq wiith a hood to bake my coils after dipping - it can do about 15 coils at a time

I use both of the end burners on low and bake for about an hour..

heres a photo of some coils that are about to be baked...

You do not have the required permissions to view the files attached to this post.

Presto Repairs - Repair/Restoration service for Presto Recording Corp cutterheads and other similar styled brands such as Audax, RCA & Universal

Re: Bobbin BBQ

Nice! Good idea.

Cutting, Inventing & Innovating

Groove Graphics, VMS Halfnuts, MIDI Automation, Professional Stereo Feedback Cutterheads, and Pesto 1-D Cutterhead Clones

Cutterhead Repair: Recoiling, Cleaning, Cloning of Screws, Dampers & More

http://mantra.audio

Groove Graphics, VMS Halfnuts, MIDI Automation, Professional Stereo Feedback Cutterheads, and Pesto 1-D Cutterhead Clones

Cutterhead Repair: Recoiling, Cleaning, Cloning of Screws, Dampers & More

http://mantra.audio

- Stevie342000

- Posts: 501

- Joined: Mon Dec 21, 2009 2:12 pm

Re: Bobbin BBQ

What, why and how? Are they baked in oil like transformers, not sure that I am following correctly.

Is there not a danger of damaging the insulation on the enamelled wire if the temperature is too high. Why not just use the regular oven with a oil bath tin and a low setting. Did the likes of Presto bake their coils?

Why dip them? Why not just place them in an oil bath? What are you dipping them in? Is it oil, varnish or wax dipped, have you tried them all, is so which did you find to give the best results and why?

What are the advantages? What does it achieve?

Why not use a dehydrator over a longer time? How did you determine the time to bake the coils for?

Is there not a danger of damaging the insulation on the enamelled wire if the temperature is too high. Why not just use the regular oven with a oil bath tin and a low setting. Did the likes of Presto bake their coils?

Why dip them? Why not just place them in an oil bath? What are you dipping them in? Is it oil, varnish or wax dipped, have you tried them all, is so which did you find to give the best results and why?

What are the advantages? What does it achieve?

Why not use a dehydrator over a longer time? How did you determine the time to bake the coils for?

- Presto Repairs

- Posts: 81

- Joined: Tue Oct 28, 2014 8:02 pm

- Location: Melbourne - Australia

Re: Bobbin BBQ

What... A bbq used to bake/cure coils that have been dipped in insulating resin

Why... A convenient way to bake/cure coils after dipping... (especially if you are married and you dont have access to an industrial oven)

The Material... An industrial resin used for sealing coils "See Photo"

YES... Presto did seal their coils with a coil resin, mainly to protect them from dust and moisture

YES... High temps can ruin coil wire coatings - Thats why I use a quality wire that is rated to 200°c and bake the coils at around 120°C (According to the crappy thermometer on the bbq hood)

I timed a batch today and they were done in a bit over 45 minutes, which was probably a little quick so the next batch I am going to run just 1 burner and let them bake/cure a little slower...

Why... A convenient way to bake/cure coils after dipping... (especially if you are married and you dont have access to an industrial oven)

The Material... An industrial resin used for sealing coils "See Photo"

YES... Presto did seal their coils with a coil resin, mainly to protect them from dust and moisture

YES... High temps can ruin coil wire coatings - Thats why I use a quality wire that is rated to 200°c and bake the coils at around 120°C (According to the crappy thermometer on the bbq hood)

I timed a batch today and they were done in a bit over 45 minutes, which was probably a little quick so the next batch I am going to run just 1 burner and let them bake/cure a little slower...

You do not have the required permissions to view the files attached to this post.

Presto Repairs - Repair/Restoration service for Presto Recording Corp cutterheads and other similar styled brands such as Audax, RCA & Universal

- Stevie342000

- Posts: 501

- Joined: Mon Dec 21, 2009 2:12 pm

Re: Bobbin BBQ

Right I see, why how and what now.

Having a quick look at the function of Impregnating Insulating Resin I see that it helps with thermal properties of the coil as well as stopping or slowing ingress of moisture and removal of the air from the coil which can affect the coil and its performance.

Did other manufacturers do the same with their coils for their cutter head? Anyone?

So essentially you dip the coil allow it to air dry and then you bake it?

In the olden days they used to bake coils in oil bath, then allow it to dry before dipping it in varnish more usual for transformers. Wax as far as I know was also used, there was more than one method of sealing the coils.

Having a quick look at the function of Impregnating Insulating Resin I see that it helps with thermal properties of the coil as well as stopping or slowing ingress of moisture and removal of the air from the coil which can affect the coil and its performance.

Did other manufacturers do the same with their coils for their cutter head? Anyone?

So essentially you dip the coil allow it to air dry and then you bake it?

In the olden days they used to bake coils in oil bath, then allow it to dry before dipping it in varnish more usual for transformers. Wax as far as I know was also used, there was more than one method of sealing the coils.

- Presto Repairs

- Posts: 81

- Joined: Tue Oct 28, 2014 8:02 pm

- Location: Melbourne - Australia

Re: Bobbin BBQ

Universal was among other companies that sealed their coils....

No... I just dip the coil in the resin, flick of the excess, hang & bake

The resin wont dry at room temperature - you need to bake it...

There are several methods to seal/ insulate coils - Ive seen a number of different materials used...

I have another method that I am currently testing out on my own cutters, but until I am satisfied that the method is worthy of making public - It will remain a secret!

No... I just dip the coil in the resin, flick of the excess, hang & bake

The resin wont dry at room temperature - you need to bake it...

There are several methods to seal/ insulate coils - Ive seen a number of different materials used...

I have another method that I am currently testing out on my own cutters, but until I am satisfied that the method is worthy of making public - It will remain a secret!

Presto Repairs - Repair/Restoration service for Presto Recording Corp cutterheads and other similar styled brands such as Audax, RCA & Universal

- Fela Borbone

- Posts: 292

- Joined: Thu Mar 07, 2013 5:22 pm

- Location: Valencia, Spain

Re: Bobbin BBQ

Temco is boss! It makes the coil a solid block, helps heat out, prevents buzzing. Helps extra insulation, but in my opinion some solid extra material to protect the coil fron the polepiece edges is welcome,

I use a mould for winding(this I do by hand, not that many turns)

and other set of moulds for baking, to ensure the exact shape fitting of the polepiesces.I use 250w infra red, with a dimmer a few centimeters away from the coils.

I use a mould for winding(this I do by hand, not that many turns)

and other set of moulds for baking, to ensure the exact shape fitting of the polepiesces.I use 250w infra red, with a dimmer a few centimeters away from the coils.

- Presto Repairs

- Posts: 81

- Joined: Tue Oct 28, 2014 8:02 pm

- Location: Melbourne - Australia

Re: Bobbin BBQ

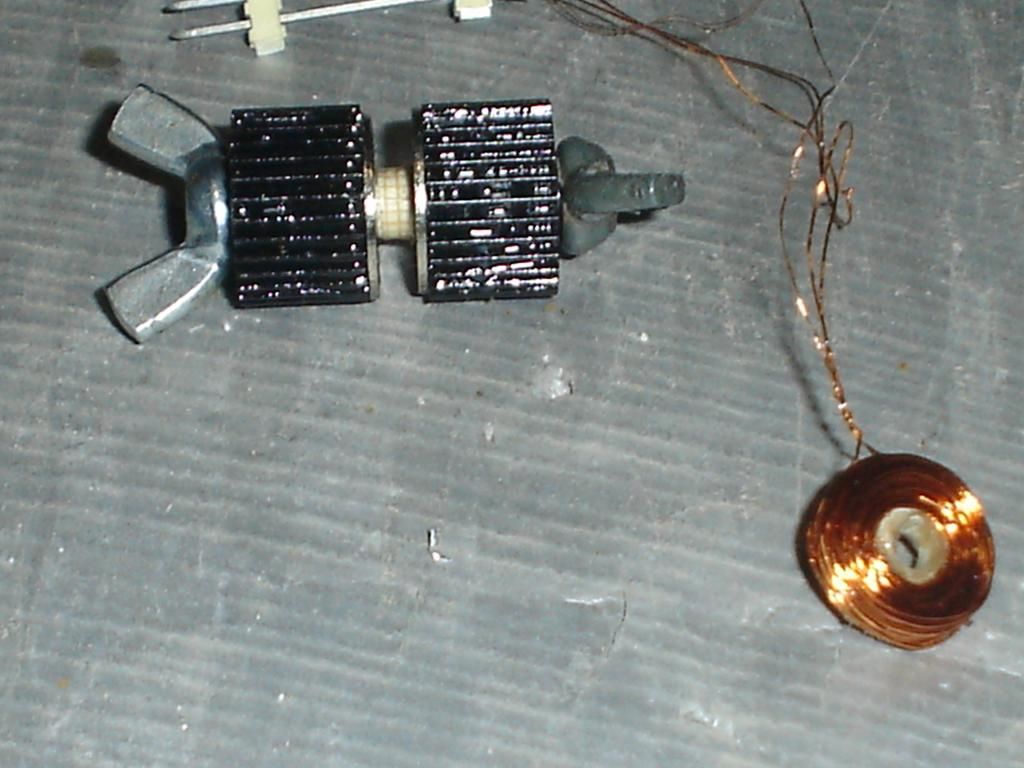

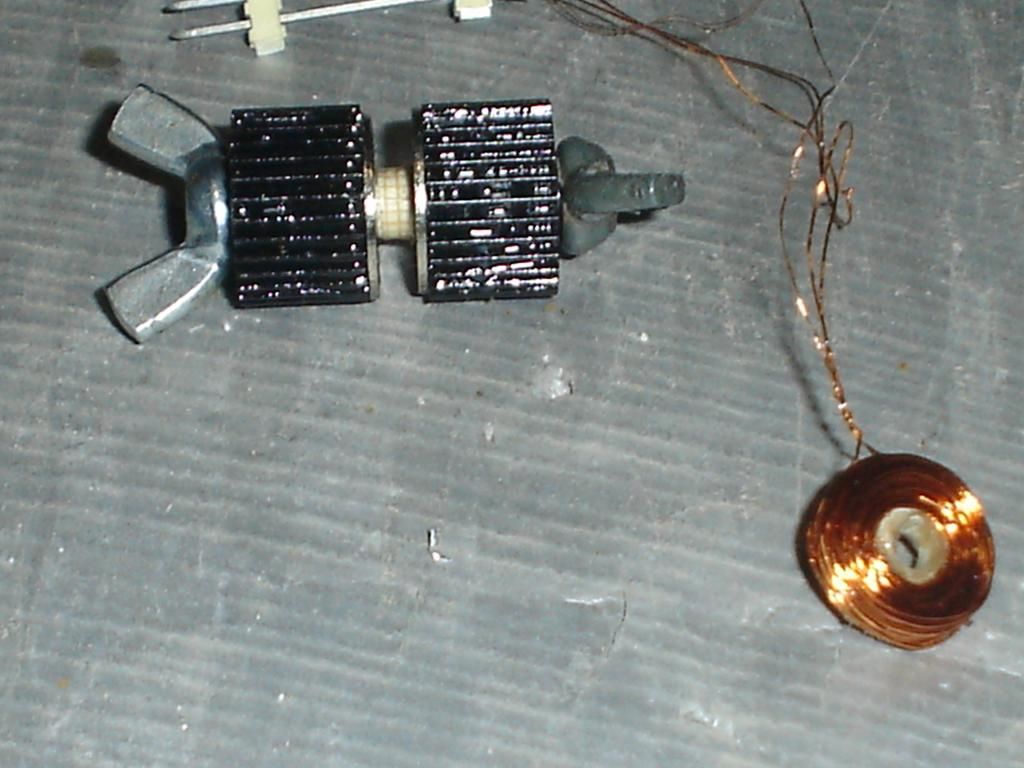

Fela Borbone wrote:Temco is boss! It makes the coil a solid block, helps heat out, prevents buzzing. Helps extra insulation, but in my opinion some solid extra material to protect the coil fron the polepiece edges is welcome.

Too right temco is boss...

I only use the best...

I love the wingnut baking moulds you have made. (Very cool)

I wind coils onto teflon machined spools which are set into a mould on my coil winder when I wind them (Also by hand) After winding, the coils are simply dipped and baked....

Presto Repairs - Repair/Restoration service for Presto Recording Corp cutterheads and other similar styled brands such as Audax, RCA & Universal

- Presto Repairs

- Posts: 81

- Joined: Tue Oct 28, 2014 8:02 pm

- Location: Melbourne - Australia

Re: Bobbin BBQ

A photo of a 5C coil in its mould, ready to be wound....

Smaller than the 1C/1D coils pictured on the bbq

Smaller than the 1C/1D coils pictured on the bbq

You do not have the required permissions to view the files attached to this post.

Presto Repairs - Repair/Restoration service for Presto Recording Corp cutterheads and other similar styled brands such as Audax, RCA & Universal

- Presto Repairs

- Posts: 81

- Joined: Tue Oct 28, 2014 8:02 pm

- Location: Melbourne - Australia

Re: Bobbin BBQ

My findings are in...Presto Repairs wrote:Universal was among other companies that sealed their coils....

No... I just dip the coil in the resin, flick of the excess, hang & bake

The resin wont dry at room temperature - you need to bake it...

There are several methods to seal/ insulate coils - Ive seen a number of different materials used...

I have another method that I am currently testing out on my own cutters, but until I am satisfied that the method is worthy of making public - It will remain a secret!

To seal or not to seal is a matter of preference as sealed and unsealed coils both have their pros and cons"

Eg:

Sealing with resin offers protection aginst moiture and offers even heat dissipation but suffers from lack of volume due to the damping

Unsealed coils offer brilliant volume levels but are prone to resontaing at higher frequencies if driven too hard due to the lack of damping...

Of late ive been using a silicone insulating wrapping tape on my coils... This tape has a high temperature rating and an insulating value of 8000 volts per layer...

In short ive been running the heads for several hours at a time with no issues...

The pros...

Good volume, damping and insulating

The cons...

Marginally resistant to moisture and dust therefore assumed to have a shorter lifespan than a resin sealed coil

I am satisfied that the method is an acceptable method of insulating + damping coil surfaces and will be offering it as a standard, The use of heat lamps and keeping your cutting area clean is considered good practice and will ensure a long coil life - however if a customer requests resin sealed coils I will provide them...

Presto Repairs - Repair/Restoration service for Presto Recording Corp cutterheads and other similar styled brands such as Audax, RCA & Universal

- Presto Repairs

- Posts: 81

- Joined: Tue Oct 28, 2014 8:02 pm

- Location: Melbourne - Australia

Re: Bobbin BBQ

My findings are in...Presto Repairs wrote:Universal was among other companies that sealed their coils....

No... I just dip the coil in the resin, flick of the excess, hang & bake

The resin wont dry at room temperature - you need to bake it...

There are several methods to seal/ insulate coils - Ive seen a number of different materials used...

I have another method that I am currently testing out on my own cutters, but until I am satisfied that the method is worthy of making public - It will remain a secret!

To seal or not to seal is a matter of preference as sealed and unsealed coils both have their pros and cons"

Eg:

Sealing with resin offers protection aginst moiture and offers even heat dissipation but suffers from lack of volume due to the damping

Unsealed coils offer brilliant volume levels but are prone to resontaing at higher frequencies if driven too hard due to the lack of damping...

Of late ive been using a silicone insulating wrapping tape on my coils... This tape has a high temperature rating and an insulating value of 8000 volts per layer...

In short ive been running the heads for several hours at a time with no issues...

The pros...

Good volume, damping and insulating

The cons...

Marginally resistant to moisture and dust therefore assumed to have a shorter lifespan than a resin sealed coil

I am satisfied that the method is an acceptable method of insulating + damping coil surfaces and will be offering it as a standard, The use of heat lamps and keeping your cutting area clean is considered good practice and will ensure a long coil life - however if a customer requests resin sealed coils I will provide them...

You do not have the required permissions to view the files attached to this post.

Presto Repairs - Repair/Restoration service for Presto Recording Corp cutterheads and other similar styled brands such as Audax, RCA & Universal

- Presto Repairs

- Posts: 81

- Joined: Tue Oct 28, 2014 8:02 pm

- Location: Melbourne - Australia

Re: Bobbin BBQ

Characteristics of the Silicone wrap being used...

• Is Self-Fusing!

• Incredible 950 PSI Tensile Strength!

• Insulates 8,000 Volts per layer!

• Withstands 500° F Degrees of heat!

• Remains flexible to -85° F! (-60° C

• Creates a Permanent Air-Tight, Water-Tight Seal in seconds!

• Never gets gummy or sticky like electrical tape - No messy cleanup!

• Has an unbelievably long shelf life!

• Resists Fuels, Oils, Acids, Solvents, Salt Water, Road Salt, UV Rays

• Neaten up lines and extension cords

• Wrap wiring harnesses and custom split-looming

• Waterproof electrical connections and terminals

In my above post, I said this product is resistant to moisture and dust The reason I didnt say "proof" is because the wrap covers the surface of the coil. - I do my best to completely wrap the coils as best as I can but there may be extremly small gaps present between the wraps edges and spool walls, particularly where the coils terminal wires protrude...

Also stated above - That the use of heat lamps and keeping your cutting area clean is good practice and will ensure a long coil life... This is because moisture + dust levels can be kept to a minimum creating a more favourable environment all round...

If you cut records under water or in dust storms then maybe you might have problems after a while, but for the rest of you who cut in a room, garage or studio - you can expect the coils to last...

• Is Self-Fusing!

• Incredible 950 PSI Tensile Strength!

• Insulates 8,000 Volts per layer!

• Withstands 500° F Degrees of heat!

• Remains flexible to -85° F! (-60° C

• Creates a Permanent Air-Tight, Water-Tight Seal in seconds!

• Never gets gummy or sticky like electrical tape - No messy cleanup!

• Has an unbelievably long shelf life!

• Resists Fuels, Oils, Acids, Solvents, Salt Water, Road Salt, UV Rays

• Neaten up lines and extension cords

• Wrap wiring harnesses and custom split-looming

• Waterproof electrical connections and terminals

In my above post, I said this product is resistant to moisture and dust The reason I didnt say "proof" is because the wrap covers the surface of the coil. - I do my best to completely wrap the coils as best as I can but there may be extremly small gaps present between the wraps edges and spool walls, particularly where the coils terminal wires protrude...

Also stated above - That the use of heat lamps and keeping your cutting area clean is good practice and will ensure a long coil life... This is because moisture + dust levels can be kept to a minimum creating a more favourable environment all round...

If you cut records under water or in dust storms then maybe you might have problems after a while, but for the rest of you who cut in a room, garage or studio - you can expect the coils to last...

Presto Repairs - Repair/Restoration service for Presto Recording Corp cutterheads and other similar styled brands such as Audax, RCA & Universal

- Presto Repairs

- Posts: 81

- Joined: Tue Oct 28, 2014 8:02 pm

- Location: Melbourne - Australia

Re: Bobbin BBQ

Here's a picture of an original presto coil,

presto also wrapped their coils with a tape before they resin sealed them

They sealed their coils mainly to protect them from moisture and dust

As stated above "unless you cut underwater or in dust storms" its not really necessary, but I will provide if requested...

presto also wrapped their coils with a tape before they resin sealed them

They sealed their coils mainly to protect them from moisture and dust

As stated above "unless you cut underwater or in dust storms" its not really necessary, but I will provide if requested...

You do not have the required permissions to view the files attached to this post.

Presto Repairs - Repair/Restoration service for Presto Recording Corp cutterheads and other similar styled brands such as Audax, RCA & Universal

Re: Bobbin BBQ

Hi is it possible to get one of these coils wound and sent to me?

I have a 5C but it's coil is in a sorry state....

I have a 5C but it's coil is in a sorry state....

Re: Bobbin BBQ

You might try emailing him. He had some changes in priorities so I'm not sure he continues to provide any services. Last post was in June and last visit to the board was in October.symatic wrote:Hi is it possible to get one of these coils wound and sent to me?

I have a 5C but it's coil is in a sorry state....

There are a few others here that I believe could also help you out, maybe they'll see your post and be in contact.

Re: Bobbin BBQ

yeah I haven't heard back from Presto Repairs in a while now which is why I'm posting here

Re: Bobbin BBQ

I can wind coils.

Cutting, Inventing & Innovating

Groove Graphics, VMS Halfnuts, MIDI Automation, Professional Stereo Feedback Cutterheads, and Pesto 1-D Cutterhead Clones

Cutterhead Repair: Recoiling, Cleaning, Cloning of Screws, Dampers & More

http://mantra.audio

Groove Graphics, VMS Halfnuts, MIDI Automation, Professional Stereo Feedback Cutterheads, and Pesto 1-D Cutterhead Clones

Cutterhead Repair: Recoiling, Cleaning, Cloning of Screws, Dampers & More

http://mantra.audio