No-label Records

Moderators: piaptk, tragwag, Steve E., Aussie0zborn

- basquiattag

- Posts: 17

- Joined: Thu Jan 14, 2010 6:11 pm

No-label Records

Hi all,

I'm told that a press needs to be reconfigured in order to press a no-label record. Is that true? And if so, is there an easy explanation as to how that's done?

thanks

I'm told that a press needs to be reconfigured in order to press a no-label record. Is that true? And if so, is there an easy explanation as to how that's done?

thanks

Press and no labels

Hey man

Someone is having a lend of you, telling you rubbish, untrue things, whatever

Ok

Now if the pins and bushes are worn than you will get a bit of flash around where the stampers are held on to the molds

If the molds pins and bushes are in top nick than there is no reason that the press will not make records without labels and without any flash or anything else for that matter

May be they need to slow it down a bit but no big deal it is just a timer that needs adjusting like turn a damn knob and increase cooling to another 1-3 seconds

So what is that re-configuring? I doubt it you do it a few times a day as part of pressing records Colder water in the morning warmer after you pressed a few thousand weather and all of that Normal stuff really

So what on earth they are talking about its beyond me

May be you have chosen the wrong pressing plant mate as it seems that they want to gouge you man

Cheers

Cheers

Someone is having a lend of you, telling you rubbish, untrue things, whatever

Ok

Now if the pins and bushes are worn than you will get a bit of flash around where the stampers are held on to the molds

If the molds pins and bushes are in top nick than there is no reason that the press will not make records without labels and without any flash or anything else for that matter

May be they need to slow it down a bit but no big deal it is just a timer that needs adjusting like turn a damn knob and increase cooling to another 1-3 seconds

So what is that re-configuring? I doubt it you do it a few times a day as part of pressing records Colder water in the morning warmer after you pressed a few thousand weather and all of that Normal stuff really

So what on earth they are talking about its beyond me

May be you have chosen the wrong pressing plant mate as it seems that they want to gouge you man

Cheers

Cheers

Chris

- basquiattag

- Posts: 17

- Joined: Thu Jan 14, 2010 6:11 pm

IMHO, the thing is not that easy, it depends on the type

of press...

on toolex presses, you have to change a little bit:

-the press detects, if a label is at the label loading arm or not,

if not, the press stops, so covering the suction cups will do the trick

-if the toolex trims the record, the inner hole gets a bit bigger,

because the label normally stablises the center hole, this can be prevented

by changing cooling cycle, but thats not so easy, if the

record is too cold, the timmer may not work anymore ...holy s....

a press with a better trimming station (a holder turntable also

from the top) will do the job better, I think....

of press...

on toolex presses, you have to change a little bit:

-the press detects, if a label is at the label loading arm or not,

if not, the press stops, so covering the suction cups will do the trick

-if the toolex trims the record, the inner hole gets a bit bigger,

because the label normally stablises the center hole, this can be prevented

by changing cooling cycle, but thats not so easy, if the

record is too cold, the timmer may not work anymore ...holy s....

a press with a better trimming station (a holder turntable also

from the top) will do the job better, I think....

- Aussie0zborn

- Posts: 1828

- Joined: Sat Mar 11, 2006 8:23 am

- Location: Australia

- Contact:

It is posible that the centre hole will stretch while the record is being trimmed.

As Andy mentions, an old American manual trimmer that clamps the record at the centre and the edges is ideal. Even the Alpha Toolex manual trimmer that clamps the record at the centre only can strectch the centre hole as the cutting knife comes into contact with the flash before the clamping takes effect.

In any case, it is not that much trouble to do it with a manual press. As MossBoss says, a little extra cooling time will do the trick. There is some mucking aroiund so a surcharge is not entriely unreasonable.

As Andy mentions, an old American manual trimmer that clamps the record at the centre and the edges is ideal. Even the Alpha Toolex manual trimmer that clamps the record at the centre only can strectch the centre hole as the cutting knife comes into contact with the flash before the clamping takes effect.

In any case, it is not that much trouble to do it with a manual press. As MossBoss says, a little extra cooling time will do the trick. There is some mucking aroiund so a surcharge is not entriely unreasonable.

- montalbano

- Posts: 139

- Joined: Tue Aug 11, 2009 3:03 pm

- Location: Settala (MI), Italy

- Contact:

Old Mossy's is around so tomorrow at 06:30 AM I'll wake him up and ask him why did he answer like this - and he'll probably tell me to fuck off! Anyway, this is my experience with Toolex presses. Which is the basically same as Andy, with the only difference that we have either manual and auto presses.

The extra cooling can minimize the problem, but it is a fact that the paper's fiber helps a lot in keeping the center hole and the whole record more stable, because the center is crucial.

So this doesn't just affect the shape of the centerhole, but also the possible dishing of a record. To understand this, just think that the PVC is - initially - an unstable material; so if you squeeze against it some fixing material, like paper which has fiber, you help it to stabilize evenly on the two sides.

Any record presser will confirm that if accidentally one record comes out from the press with just one label on one side only, it will immediately tend to dish.

The PVC cooling happens not just inside the press; it goes on after. You can put spacers to keep the record flat, but without labels, what will happen to the center hole without anything helping to keep its formed shape?

So if you press a record without labels, you can't tell. It might be good, it might not. If there is absolutely no difference in heating transfer between the A&B moulds and if the centerpins are 100% A OK, then you can let the record rest for a while and it will be probably be OK. A 7" more probably, a 12" a little bit less.

So in my opinion, it is worth to spend 80 - 100€ or whatever more and get monochrome or even quadrichrome offset printed labels: no issues and a 100% industrial-quality product.

And if you decide to go with white labels and you plan to stick adhesive labels over them, don't expect big results. The 100 tons of pressure of any press will slightly enlarge the labels' diameter, with the result that you will have something slightly smaller stuck against something slightly bigger. Result = shit.

The wheel is that ... why trying to change that?

The extra cooling can minimize the problem, but it is a fact that the paper's fiber helps a lot in keeping the center hole and the whole record more stable, because the center is crucial.

So this doesn't just affect the shape of the centerhole, but also the possible dishing of a record. To understand this, just think that the PVC is - initially - an unstable material; so if you squeeze against it some fixing material, like paper which has fiber, you help it to stabilize evenly on the two sides.

Any record presser will confirm that if accidentally one record comes out from the press with just one label on one side only, it will immediately tend to dish.

The PVC cooling happens not just inside the press; it goes on after. You can put spacers to keep the record flat, but without labels, what will happen to the center hole without anything helping to keep its formed shape?

So if you press a record without labels, you can't tell. It might be good, it might not. If there is absolutely no difference in heating transfer between the A&B moulds and if the centerpins are 100% A OK, then you can let the record rest for a while and it will be probably be OK. A 7" more probably, a 12" a little bit less.

So in my opinion, it is worth to spend 80 - 100€ or whatever more and get monochrome or even quadrichrome offset printed labels: no issues and a 100% industrial-quality product.

And if you decide to go with white labels and you plan to stick adhesive labels over them, don't expect big results. The 100 tons of pressure of any press will slightly enlarge the labels' diameter, with the result that you will have something slightly smaller stuck against something slightly bigger. Result = shit.

The wheel is that ... why trying to change that?

Plain Nolabel records

Many thousands of records have been produced without labels

Its no big deal at all

If you have worn dies and bushes most of the above apply but that is not really the point

A good pressing plant will not have worn out dies pins or buses so it should not be any real issue

Despite the suggestions it is as simple as this

After a few thousand records the bottom as well as the top pin wear a bit from a sliding fit to a loose fit

You can see it in records which have a rough finish around the hole

Now the label stops quite a bit of the compound getting into the tiny space between pin and bush as it forms a "seal" but not a very good one

If you want to lower your pressure so as to not drive the material down the space between the pin and bush you will finsh up with non fill for sure

However that is not the idea the pin should be always a sliding fit into the bush with no lateral play at all

If it has play than you will get a wonky hole a non filled record or a bad looking finsh around the hole

On another point

The Alpha press uses vacuum so as to hold down the record on to the trimming table,

It is held there strictly by the atmospheric pressure exerted upon it as the vacuum necessary to bring the pipes and the holes under vacuum its not that strong

As a crude guess the amount of pressure exerted on the record while on the trimming table under vacuum is around the 1800 pounds or 3/4 of a tonne

The unloader arm will bring it out of the dies directly above the table

The table will raise at the same time as the pusher comes down and it will be held on to the table as above a little vacuum and atmospheric pressure

There is a taper pin that locates the record center to the trimmer

It works very well but the suction cups on the tranfer/unloader arm MUST be very flexible so as to give a little so the record is guided by the taper pin and it is centered prior to been sucked down on the table

Now a record that is removed a bit hotter than it should be as well as a set of 3 stiff suction cups and a maladjusted press one will end up wih an elongated hole

It is as simple as that

Keeping in mind that the hardest part to cool down is the center as it reliant on cooling down by the material adjacent to it ie the die/mould itself

So a set of bushes that are mushroom headed if available will make a thinner section there helping the cooling down process greatly

Now if any one sees the Columbia profile with the 2" diameter bush of days gone past will appreciatte the facts above as this was most likely the best answer to a reall issue with stampers, labels, and cooling down of the center section of the record

This bush was 2" in diameter very thin up the top but it conducted heat away in the cooling down cycle in a much better way than anything else used at the time or since

It also had a very fine thread at the bottom where one could adjust the right tension on the stamper so as to not finish up with a rough finish

A very fine design indeed

It has allways been the case in the past that records should be made as thin as possible, material saving was the aim of course

There has been quite a few profiles developed over many years by various mold manufacturers

So the die itself has a rather interesting profile even though it looks flat from the label area out, it is not flat at all

It has a deepening section going out to about a third of the way than it gets thinner all the way to the starting groove where one has a "bead"

This design than creates the necessary tension on the record so as to stay flat, given it was pressed under the right conditions

Now days this knowledge has almost dissapeared so profiles are a bit of a hit and miss affair in particular when a machine shop re profiles the moulds due to wear pitting superficial damage etc

I am sure people here have real thin records which are still perfectly flat even though they where made many years ago

So as to prove the point take one and cut it right across the middle and have a look at the varying thicknes of the vinyl

It can be seen quite clearly do the same with some recent pressings There may be a surprise there to a few people

Now if any one is trying to convince me or any good pressing man out there that the label will stop material getting down a worn out pin under 100 tonne of pressure with the puck at around the 120-130 C which than is heated before getting pressed with the additional steam heat in the moulds at around the 155-160 C they will be hard pushed to convince me or any one else for that matter

Try to make a puck/cake at around the 150 C on the extruder and see what the Alpha will do with it?

Why not why add the extra heat when the cake is in the dies

Do it with the extruder, is quite capable of doing it

Have a think about it

Now why on earth am I going down this very detailed description or path to a simple question that started this thread?

Well there seems to be a couple or a few Toolex man here who may need to really understand how things really work on the press

In summary

If any one is relaying on the labels so as to prodce a good hole on the record when the gear they use its not up to scratch they should look at their pressing equipment as well as their procedures very closely or look at the adjustment of the very fine Alpha press again and set it up correctly

By the way We do the first few shots on any test pressing without labels until the dies settle down after we run the machine on test for about 20 minutes with all functions on apart from hydralics of course

This than prevents us having to punch the center out before the rejected first pressings go to the granulator bin or how some people here call it, the Mill

Cheers

Its no big deal at all

If you have worn dies and bushes most of the above apply but that is not really the point

A good pressing plant will not have worn out dies pins or buses so it should not be any real issue

Despite the suggestions it is as simple as this

After a few thousand records the bottom as well as the top pin wear a bit from a sliding fit to a loose fit

You can see it in records which have a rough finish around the hole

Now the label stops quite a bit of the compound getting into the tiny space between pin and bush as it forms a "seal" but not a very good one

If you want to lower your pressure so as to not drive the material down the space between the pin and bush you will finsh up with non fill for sure

However that is not the idea the pin should be always a sliding fit into the bush with no lateral play at all

If it has play than you will get a wonky hole a non filled record or a bad looking finsh around the hole

On another point

The Alpha press uses vacuum so as to hold down the record on to the trimming table,

It is held there strictly by the atmospheric pressure exerted upon it as the vacuum necessary to bring the pipes and the holes under vacuum its not that strong

As a crude guess the amount of pressure exerted on the record while on the trimming table under vacuum is around the 1800 pounds or 3/4 of a tonne

The unloader arm will bring it out of the dies directly above the table

The table will raise at the same time as the pusher comes down and it will be held on to the table as above a little vacuum and atmospheric pressure

There is a taper pin that locates the record center to the trimmer

It works very well but the suction cups on the tranfer/unloader arm MUST be very flexible so as to give a little so the record is guided by the taper pin and it is centered prior to been sucked down on the table

Now a record that is removed a bit hotter than it should be as well as a set of 3 stiff suction cups and a maladjusted press one will end up wih an elongated hole

It is as simple as that

Keeping in mind that the hardest part to cool down is the center as it reliant on cooling down by the material adjacent to it ie the die/mould itself

So a set of bushes that are mushroom headed if available will make a thinner section there helping the cooling down process greatly

Now if any one sees the Columbia profile with the 2" diameter bush of days gone past will appreciatte the facts above as this was most likely the best answer to a reall issue with stampers, labels, and cooling down of the center section of the record

This bush was 2" in diameter very thin up the top but it conducted heat away in the cooling down cycle in a much better way than anything else used at the time or since

It also had a very fine thread at the bottom where one could adjust the right tension on the stamper so as to not finish up with a rough finish

A very fine design indeed

It has allways been the case in the past that records should be made as thin as possible, material saving was the aim of course

There has been quite a few profiles developed over many years by various mold manufacturers

So the die itself has a rather interesting profile even though it looks flat from the label area out, it is not flat at all

It has a deepening section going out to about a third of the way than it gets thinner all the way to the starting groove where one has a "bead"

This design than creates the necessary tension on the record so as to stay flat, given it was pressed under the right conditions

Now days this knowledge has almost dissapeared so profiles are a bit of a hit and miss affair in particular when a machine shop re profiles the moulds due to wear pitting superficial damage etc

I am sure people here have real thin records which are still perfectly flat even though they where made many years ago

So as to prove the point take one and cut it right across the middle and have a look at the varying thicknes of the vinyl

It can be seen quite clearly do the same with some recent pressings There may be a surprise there to a few people

Now if any one is trying to convince me or any good pressing man out there that the label will stop material getting down a worn out pin under 100 tonne of pressure with the puck at around the 120-130 C which than is heated before getting pressed with the additional steam heat in the moulds at around the 155-160 C they will be hard pushed to convince me or any one else for that matter

Try to make a puck/cake at around the 150 C on the extruder and see what the Alpha will do with it?

Why not why add the extra heat when the cake is in the dies

Do it with the extruder, is quite capable of doing it

Have a think about it

Now why on earth am I going down this very detailed description or path to a simple question that started this thread?

Well there seems to be a couple or a few Toolex man here who may need to really understand how things really work on the press

In summary

If any one is relaying on the labels so as to prodce a good hole on the record when the gear they use its not up to scratch they should look at their pressing equipment as well as their procedures very closely or look at the adjustment of the very fine Alpha press again and set it up correctly

By the way We do the first few shots on any test pressing without labels until the dies settle down after we run the machine on test for about 20 minutes with all functions on apart from hydralics of course

This than prevents us having to punch the center out before the rejected first pressings go to the granulator bin or how some people here call it, the Mill

Cheers

Chris

- gottagroovematt

- Posts: 12

- Joined: Tue Mar 17, 2009 12:15 am

- Location: Ohio

no labels

Actually, we just started pressing no-label records at the request of a couple customers. The center holes do tend to distort inevitably, but we seem to have it down to a minimum at this point. The records do tend to stick to the stampers a bit too. But, as of the first official run of them last week, they came out well.

- Aussie0zborn

- Posts: 1828

- Joined: Sat Mar 11, 2006 8:23 am

- Location: Australia

- Contact:

Matt, if the record sticks to the stamper around the outer edge of the centre bush, you can solve this problem by using a brass washer a few millimetres larger in diameter than the diameter of the centre bush. You glue it to the face of the bush with Araldite which can be easily removed when done. This method also stops the outside of the bush from tearing labels in case the bush does not sit flush in the mould. This can happen when the stamper is too thick or the edge of the bush is worn or damaged.

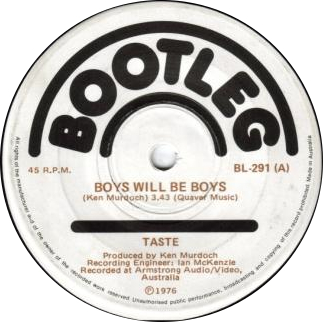

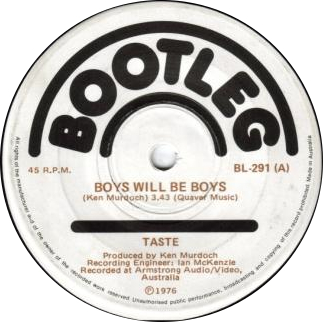

See pic below that uses this method.

See pic below that uses this method.

EMI 1400

WTF only one company used these presses and it was EMI There have been 1000's of other presses made used by hundreds of plants around the world

So a specialty extremely good press like the 1400 is no example

EMI did pioneer the injection moulded 7" that used no labels

Roy Mathews Geoff Pullen and Chris, cant rememebr the second name, are still around Check with them

I do also suspect that the 1400 will make records without labels as I have seen them

Pins and bushes have to be perfect with stamper thickness controlled so as to prevent flash around the bush No big deal

By the way Alpha as well as SMT and Lened, in actual fact all auto presses use some method to place labels either side of the puck

By the way what happens when the operator goes to sleep and the magazine runs out of labels? assuming the safety sensor on the mags does not work?

You make records without labels thats what happens If it can be done accidently it can be done deliberately

Simple

WTF only one company used these presses and it was EMI There have been 1000's of other presses made used by hundreds of plants around the world

So a specialty extremely good press like the 1400 is no example

EMI did pioneer the injection moulded 7" that used no labels

Roy Mathews Geoff Pullen and Chris, cant rememebr the second name, are still around Check with them

I do also suspect that the 1400 will make records without labels as I have seen them

Pins and bushes have to be perfect with stamper thickness controlled so as to prevent flash around the bush No big deal

By the way Alpha as well as SMT and Lened, in actual fact all auto presses use some method to place labels either side of the puck

By the way what happens when the operator goes to sleep and the magazine runs out of labels? assuming the safety sensor on the mags does not work?

You make records without labels thats what happens If it can be done accidently it can be done deliberately

Simple

Chris

- Aussie0zborn

- Posts: 1828

- Joined: Sat Mar 11, 2006 8:23 am

- Location: Australia

- Contact:

- Aussie0zborn

- Posts: 1828

- Joined: Sat Mar 11, 2006 8:23 am

- Location: Australia

- Contact:

Correct me if Im wrong but the SMT. Lened, Miller and Hamilton presses and the CBS auto system apply a label to each side of the puck and then this whole thing is placed in the press. The Alpha places the labels in the press and then the puck is inserted, in the same way as a manual press would be loaded. Is this not correct?

At the start of the steps the two label magazines are activated by air pressure pushing a label on the stationary label arms where there are 4 suction cups which suck off with vacuum a label each side

The Label arm waits for the cake loader to be activated with the two labels from the mags upper and lower A and B

It then swings in, based the classical Alpha 3 post design into the opened moulds as it is mounted on one of the press columns

The cake loader travels about 24 odd inches from the extruder cake former carrying the puck in a fork right on to the centre of the moulds

the labels are held with vacuum on to the arms, two brass plates with enough space in between them to allow the cake to enter

The pins are than activated down for the upper up for the lower which pierces the cake through the holes on labels

So the labels are held on to the pins so is the cake

That action holds them in place so you have a 2 labels and cake sandwich

The cake loader retracts to its starting position so do the label arms ready for the next cycle

press closes etc etc etc

Cheers

The Label arm waits for the cake loader to be activated with the two labels from the mags upper and lower A and B

It then swings in, based the classical Alpha 3 post design into the opened moulds as it is mounted on one of the press columns

The cake loader travels about 24 odd inches from the extruder cake former carrying the puck in a fork right on to the centre of the moulds

the labels are held with vacuum on to the arms, two brass plates with enough space in between them to allow the cake to enter

The pins are than activated down for the upper up for the lower which pierces the cake through the holes on labels

So the labels are held on to the pins so is the cake

That action holds them in place so you have a 2 labels and cake sandwich

The cake loader retracts to its starting position so do the label arms ready for the next cycle

press closes etc etc etc

Cheers

Chris

MossBoss

You seem to be quite the fountain of knowledge.

If you had seen an EMI 1400 press you would obviously know that if you attempt to press a record without labels the shot cup continues to fill with pvc until the PLC times out but before this happens the label cassette fills with PVC completely encasing the label pins and creating a 30 min problem. The 1400 was quite a successful press. It was used in over 26 plants around the world. No-one outside of EMI has any experience with them so you are indeed a very well informed man.

Yes Roy Matthews is still around and running a plant that makes about 100k records per week. And yes I know him. I did my engineering cadetship at Hayes in the 70s. Roy and I still talk. I asked him if he knows of you. He told me about your visit. He said that you were quite forthcoming with your expansive knowledge. Roy is quite a diplomat and quite good at listening.

You might be able to help me with something though. There was a guy who ran a small plant in Sydney. He used to bother me with a lot how to questions.When we were closing the Homebush plant he scavenged some equipment I think. I've forgotten his name. I think he went broke. He had a motley collection of gear. Whatever happend to him and that plant? Not sure really. Ive moved in to the print game.

Bob K

You seem to be quite the fountain of knowledge.

If you had seen an EMI 1400 press you would obviously know that if you attempt to press a record without labels the shot cup continues to fill with pvc until the PLC times out but before this happens the label cassette fills with PVC completely encasing the label pins and creating a 30 min problem. The 1400 was quite a successful press. It was used in over 26 plants around the world. No-one outside of EMI has any experience with them so you are indeed a very well informed man.

Yes Roy Matthews is still around and running a plant that makes about 100k records per week. And yes I know him. I did my engineering cadetship at Hayes in the 70s. Roy and I still talk. I asked him if he knows of you. He told me about your visit. He said that you were quite forthcoming with your expansive knowledge. Roy is quite a diplomat and quite good at listening.

You might be able to help me with something though. There was a guy who ran a small plant in Sydney. He used to bother me with a lot how to questions.When we were closing the Homebush plant he scavenged some equipment I think. I've forgotten his name. I think he went broke. He had a motley collection of gear. Whatever happend to him and that plant? Not sure really. Ive moved in to the print game.

Bob K

WTF

- Aussie0zborn

- Posts: 1828

- Joined: Sat Mar 11, 2006 8:23 am

- Location: Australia

- Contact:

Hi Bob. Welcome to the Lathe Trolls. A lot of plants went broke back then but that 'motley collection of gear" which worked well for Astor Records is still pressing records today. I think that guy owns a succesful business in the professional audio industry now - I'm sure Mossy can fill you in.

Stick around and if you are lucky you might be bothered with a lot more questions. All the best !!

Stick around and if you are lucky you might be bothered with a lot more questions. All the best !!

Oh yeah BobK

Got the other guys name Bob K... I think it is you! Is that so?

His name is Chris Adams you should know him

By the way if you stick a bit of ptfe coated round bit of metal cut to size either for the 7" or the 12" labels in to the label magazines of the 1400 it will not cause a half an hour issue

That was common practice on them by the way Bob, so as to make records without labels testing stampers etc etc etc

Surprised that you did not mentioned it but than again it is fine detail as well as a long time ago

Not sure about the guy you are refering to

Was there a couple of SMT's there in the plant as well as the other moteley collection of gear?

This may help me a bit as there was a plant in Brookvale one in around Bexeley way another way out Homebush way as well besides the major plants

There was at least another 4 or 5 in Melbourne Besides Astor and the majors with a fellow by the name of Latimer??? running the last one until recent times around the mid 90's

Oh question for you Whatever happened to the W&D 801 or 2 album folder you had if it is you?

Cheers

Got the other guys name Bob K... I think it is you! Is that so?

His name is Chris Adams you should know him

By the way if you stick a bit of ptfe coated round bit of metal cut to size either for the 7" or the 12" labels in to the label magazines of the 1400 it will not cause a half an hour issue

That was common practice on them by the way Bob, so as to make records without labels testing stampers etc etc etc

Surprised that you did not mentioned it but than again it is fine detail as well as a long time ago

Not sure about the guy you are refering to

Was there a couple of SMT's there in the plant as well as the other moteley collection of gear?

This may help me a bit as there was a plant in Brookvale one in around Bexeley way another way out Homebush way as well besides the major plants

There was at least another 4 or 5 in Melbourne Besides Astor and the majors with a fellow by the name of Latimer??? running the last one until recent times around the mid 90's

Oh question for you Whatever happened to the W&D 801 or 2 album folder you had if it is you?

Cheers

Chris

EMI Australia did not have any make up machines.

All of our print was outsourced.

Vinylfactory owns 2 machines for cutting folding and gluing standard sleeves and 1 machine for gatefold w/remus spine.

For 'testing' stampers' we used white labels or overuns from other jobs turned backwards. That was our common practice. We had no cause for making records with out labels. I am intregued how you became so knowledgable about the 1400. Did you work at Homebush or Hayes? We were always quite careful to protect the proprietry nature of our research & develpoment. EMI had a full laboritory constantly testing and implementing refinements all under Roy matthews direction. There was a strict policy of keeping this information in house.

All of our print was outsourced.

Vinylfactory owns 2 machines for cutting folding and gluing standard sleeves and 1 machine for gatefold w/remus spine.

For 'testing' stampers' we used white labels or overuns from other jobs turned backwards. That was our common practice. We had no cause for making records with out labels. I am intregued how you became so knowledgable about the 1400. Did you work at Homebush or Hayes? We were always quite careful to protect the proprietry nature of our research & develpoment. EMI had a full laboritory constantly testing and implementing refinements all under Roy matthews direction. There was a strict policy of keeping this information in house.

WTF