Here’s a question about labels from a newbie!

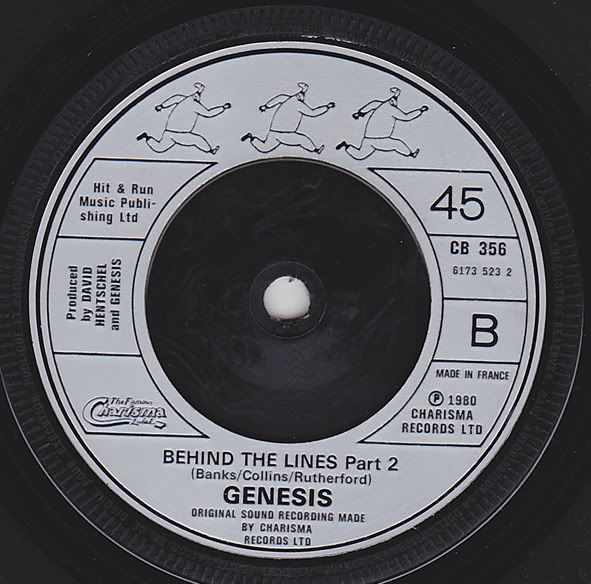

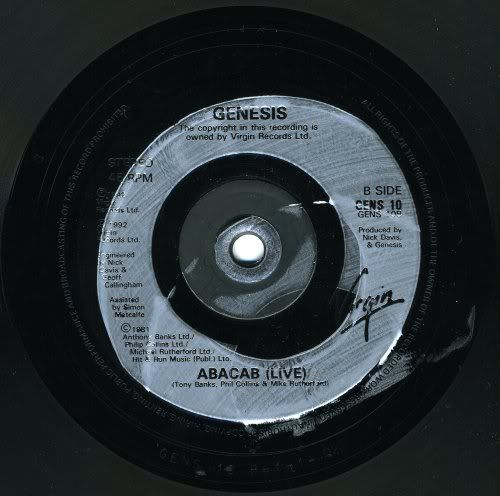

I have discussed the manufacturing process of 7” vinyl singles with a friend and I guess this will the best place to get the correct answer. My question is how the labels are made and I have seen clips on YouTube where paper labels are attached when the record is pressed. If the label is printed/painted on the record like the one on the attached picture I guess the label imprint must be in the stamper. I believe it's done like this: When the record is pressed there will be a negative "print" on the record and after that it passes a printing machine (maybe a tampon/pad printer) that has a large round pad that adds the paint. Is that correct or is it done in any other way?

I have seen this done at the Märklin model train factory were they used this technique for the thin lines, letters and logos on locomotives and coaches.

I am a record collector mainly but I also have a general interest in technical stuff and it is really amazing to read about the machines used to produce a vinyl record. I understand that this forum is full of knowledge of all parts in the record manufacturing process. I'm impressed!

All the best

Lars