In my first attempt above, I tried to reproduce the FB of a profesional cutterhead, (except for the relative size of the coils and some other things).But now I go my own way, because une FB coil above and one bellow are not posible to tune for a wide frequencies,(at least at the size I'm using)Tuning it at 1khz (more or less the resonant frequency of this system) can only figth the resonance peak,but more range is desirable.They are exposed to different amounts of drive influence (as they are at different distance)so for cancelling they have diferent number of turns,and,different self inductance, this is why if they are tuned to cancel some frequencies its pahse changes and dont work to others.

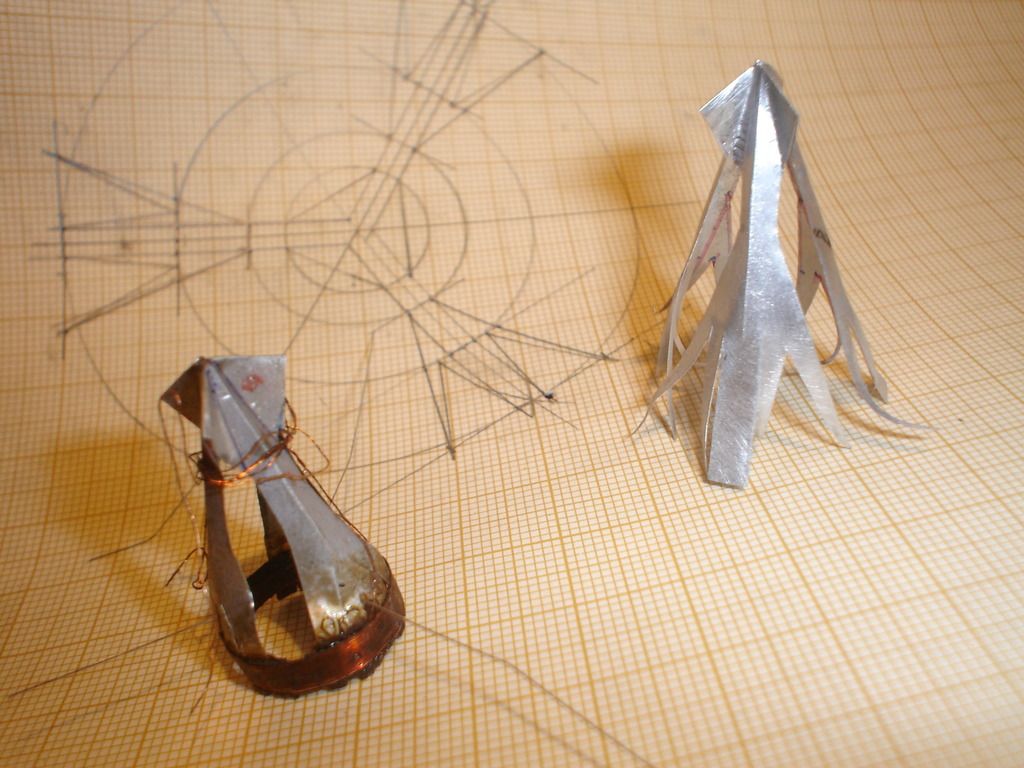

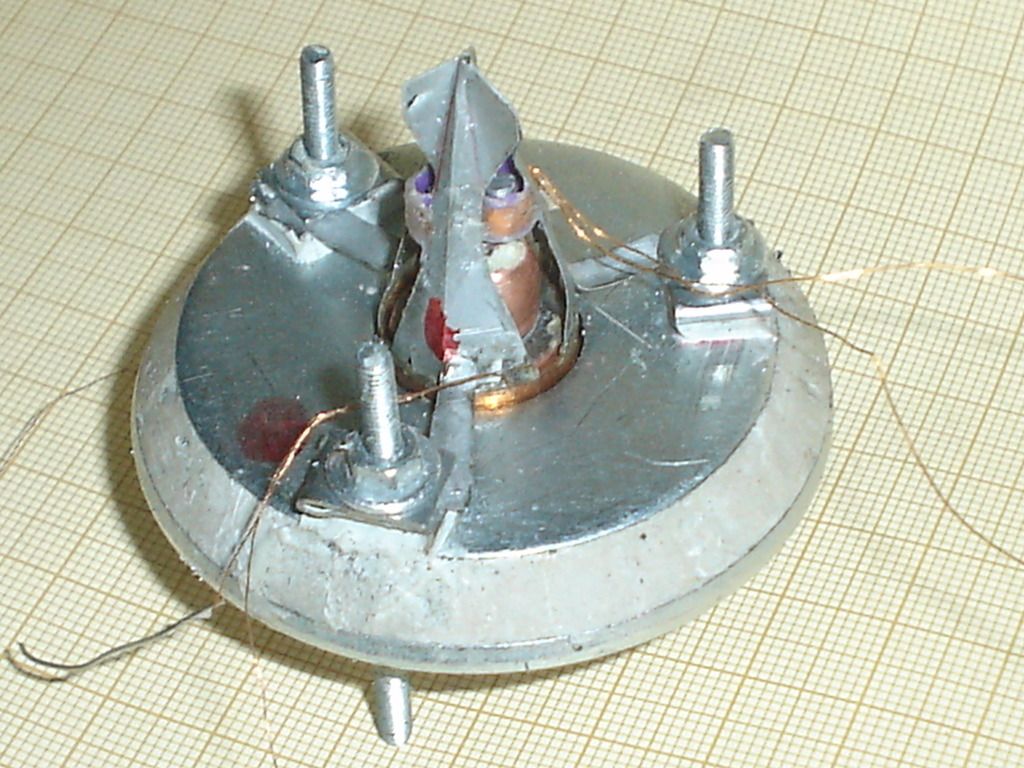

So this time Itried a system where the coils are identical, situated at the same distance to the drive.The oppositte magnetic fields are more complex to create now, I cheated a bit with the magnetic simulator(It has no 3d capabilities only planar or axis-simetric)but but I found a solution.This time the outer ring closing the magnetic circuit improves the sound signal.

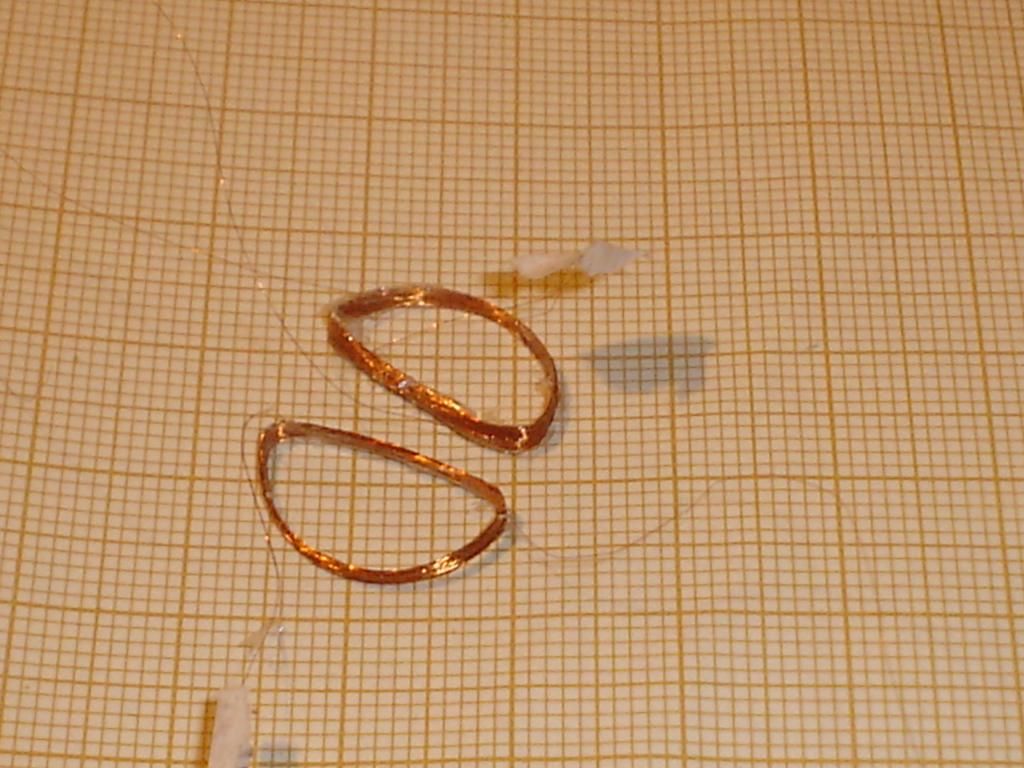

some photos:

Now cancellation is achieved along allmost all the spectrum, but some others ussues arise.Phase shifts are my next objetive.This second try was a little step forward.No recording tests yet,as I dont want to waste plastic on vain.Now Im working on the third.Im experimenting with lower indutances and the "bottle shape"that can be seen in other FB systems coil formers, after all magnetic field around coils looks like doughnuts.

Thanks for reading!

i,

i,