Moderators: piaptk, tragwag, Steve E., Aussie0zborn

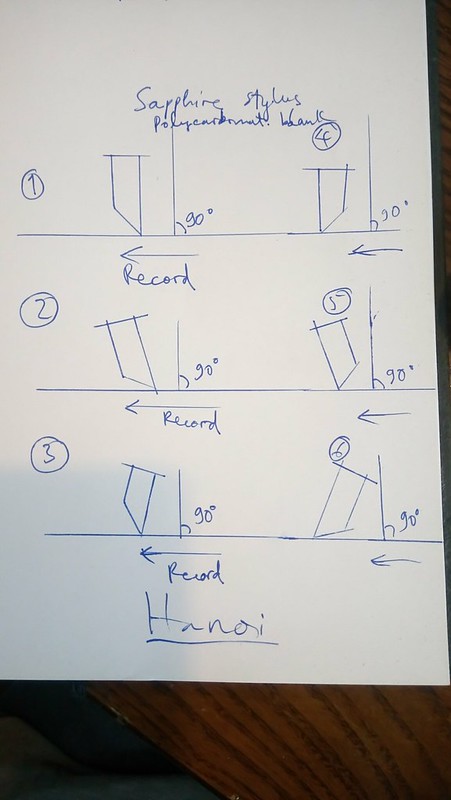

Thank you Jjwharris, I need to learn more and more!jjwharris wrote:Hey that's looking great! Are you cutting or embossing? Bryan made some interesting posts about the vta/angle of cutting when designing your cutting head which could be if interest to you.

The posts are on this page https://www.lathetrolls.com/viewtopic.php?f=15&t=5371&start=560

Thank you jjwharris, I dont understand why should turn around 180 degreesjjwharris wrote:You can however emboss with them by turning them around 180 degrees...

Thank you Mark, however its hard for me to find a dashpot in my local, may use a simple spring instead!markrob wrote:Hi,

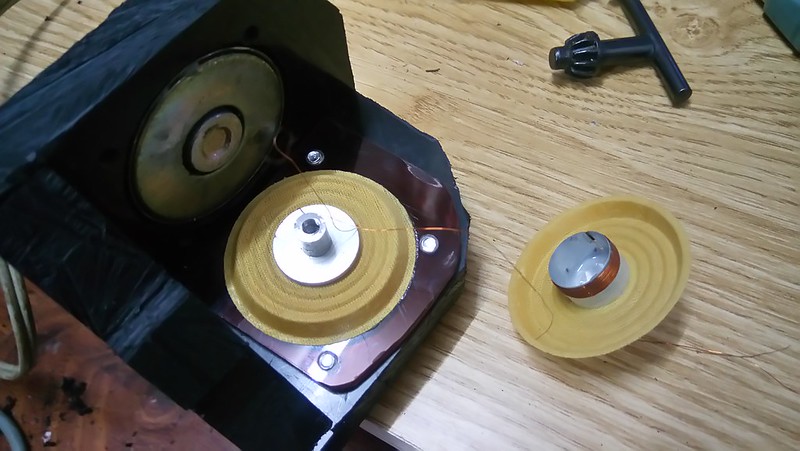

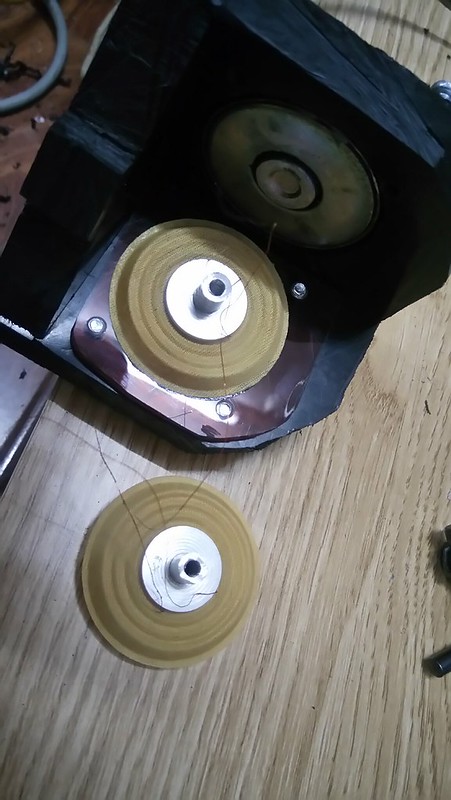

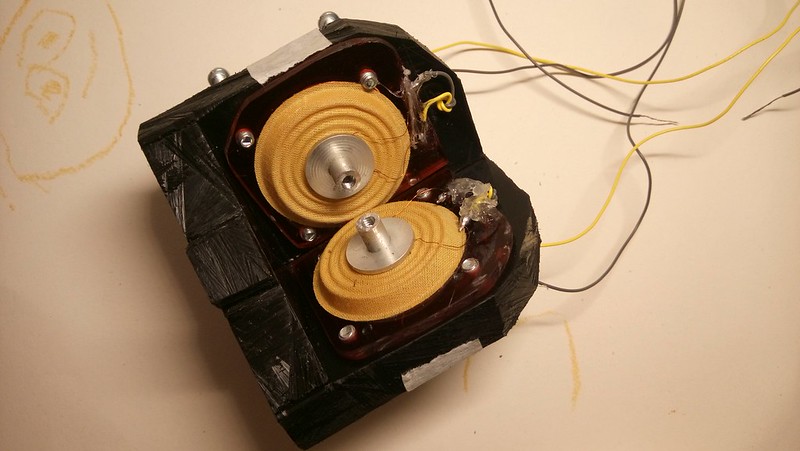

Nice looking head. It will be interesting to see how it performs. Looks like your moving mass id getting up there in size. Try to get it in the 1-2 gram range if you can.

The dashpot is used to add damping to the head suspension. Since it just a spring/mass system, it will tend to oscillate at its natural resonant frequency. Undamped, it becomes possible to excite this resonance due to platter runnout and slight warps in the blank. Damping is added via the dashpot to achieve critical damping (that is no overshoot or ringing). That leaves you with a second order low pass mechanical filter with no response peak at cutoff. Too much damping is not a good thing as it will slow down the response of the head suspension. Picking the right resonance is also important so that you track disturbances.

You can use a dashpot in the mode described in the other post. That would be in addition to the floating head suspension.

Mark

Yeah, Mark, I will try to make simple one, hope it help for next testmarkrob wrote:Hi,

You can make one pretty easily. Just imagine a washer attached to a rod that is immersed in a small can containing a viscous fluid (e.g. mineral oil)

See the pictures below of a Presto damper

Cheers!

Cheers!Hi jjwhrris,jjwharris wrote:Are you embossing or cutting?

This is a good thread to read about embossing.

https://www.lathetrolls.com/viewtopic.php?f=15&t=2945&start=20

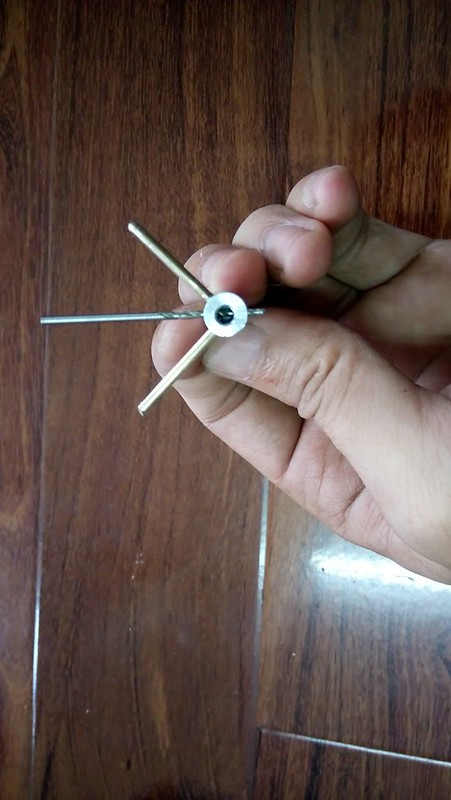

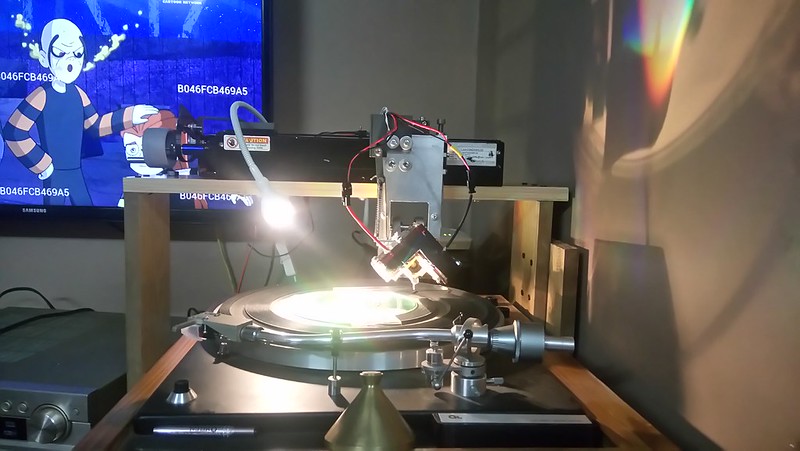

Thanks Gridlock,Gridlock wrote:Haha that looks great. From your diagram I would use angle 1 or 3. How is the playback? You should post a sample of that. It almost looks like you're cutting on ACRYLIC and not PVC? I doubt you will get enough power from that turntable motor but to experiment