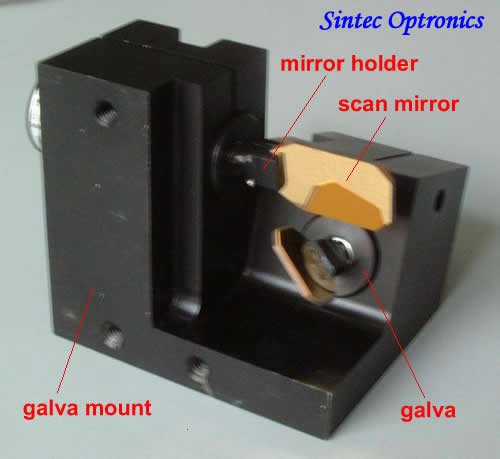

also have a resolution of 0.001" or 0.0254mm step.

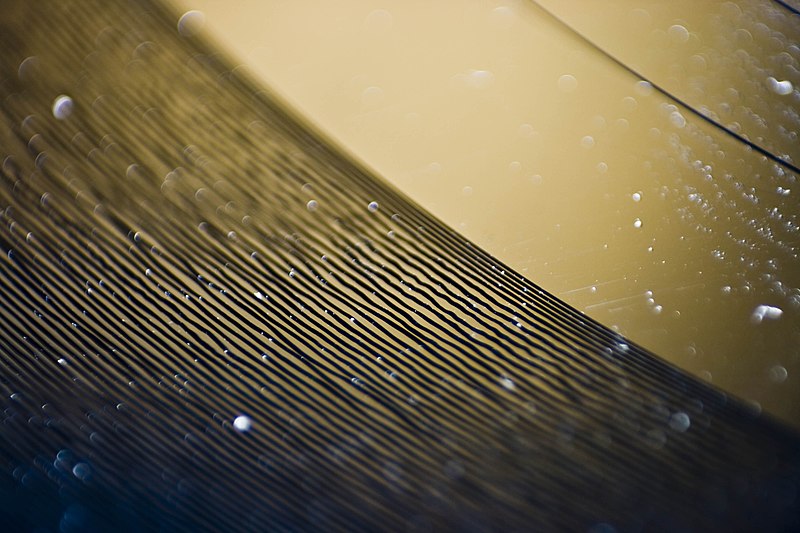

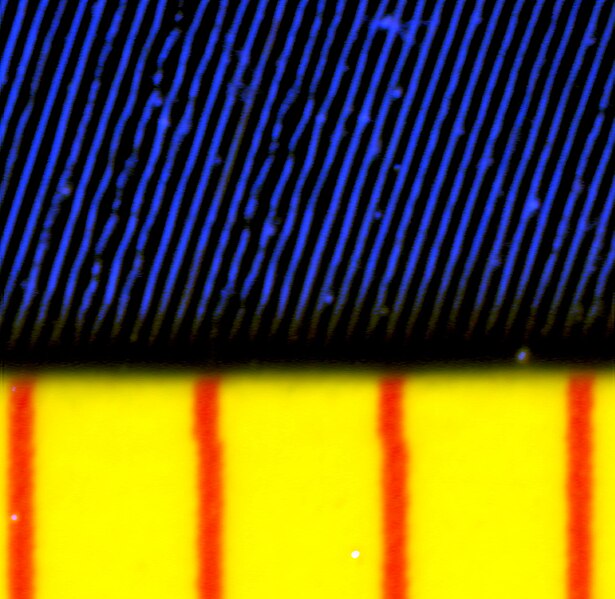

= more than "20 grooves per milimeter."

the cutting shape can be drawm in software.!!

it would have steady groove separations, not variable volume grooves but...

http://en.wikipedia.org/wiki/Gramophone_record#Structure