I have recently designed a very fancy Current-Regulated Power Supply Unit for stylus heating wires, for a small company called Magnetovolt. While I cannot make this design public, I am offering here some very simple approaches to stylus heat, which we tried out and rejected as a commercial design.

They work but they all have their limitations. However, they are simple and cheap so they can definitely get you going.

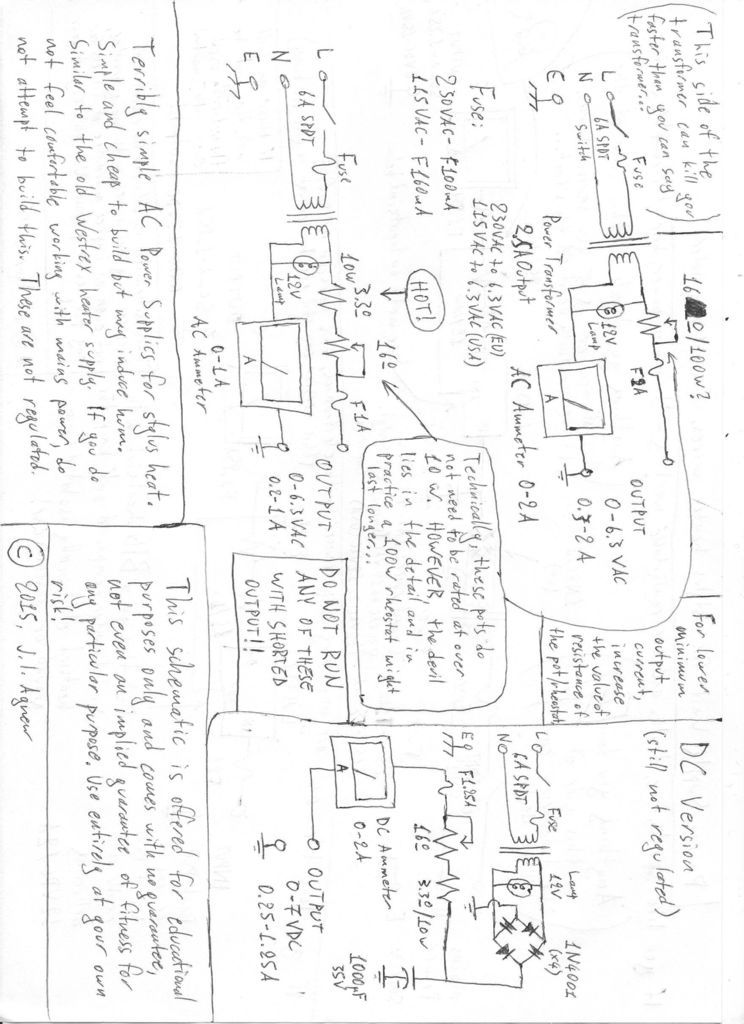

These are the simplest ones. The AC versions were even used in professional systems in the past, but are likely to induce some hum. The DC version overcomes this but none of these are properly regulated, so could drift.

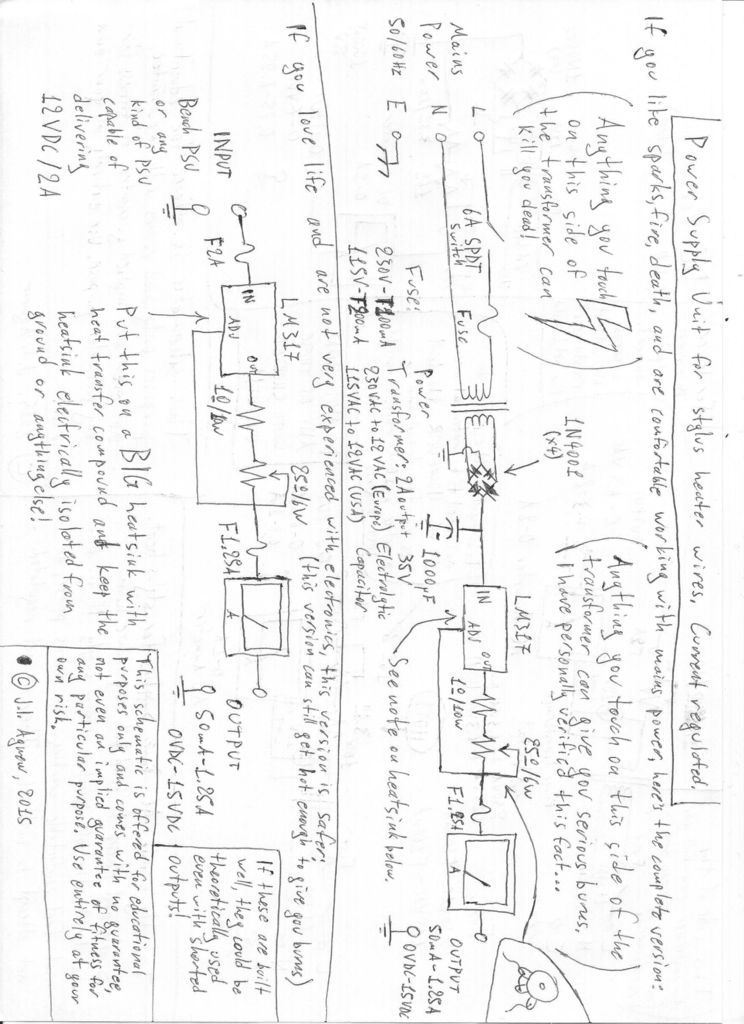

These are simple Current-Regulated versions that work well, but run pretty hot. All of these designs are a bit too simple, putting a lot of strain on the components. They will work for a bit, but can't say how long they would last. It greatly depends on the quality of the components you use.

The main thing I don't like about such designs is that plenty of current runs through the pot, which is the weakest link. You either need a very expensive industrial rheostat or you risk premature failure.

The Magnetovolt philosophy is that gear should be passed on to grandchildren and should still be as reliable as when it was made, so the final design I did was a lot more complicated, with the significant advantage that the current does not run through the pot. The whole thing runs a lot cooler. Also, it offers a very smooth and precise control of the heating current, which ranges from an almost total 0A to 1.6A, capable of accommodating all kinds of heater wire. Proper bulletproof design. It can run forever with shorted outputs and the current set to MAX!

It will come in a 2U 19" rack format, with a big Ammeter and Voltmeter on the front panel, along with a big status indicator so you always know if it's on or off. Production should start soon and I will be posting some pictures of the first units.

So, the schematics posted are good for the hobbyist on a tight budget to get started with a heated stylus setup. If you need a professional, reliable and ready-to-go solution, just wait for the Magnetovolt product. Prices should be fairly reasonable.