Hello everyone. Glad to be here (I have lurked off and on for a while). Thanks in advance for all your patience and help. I'm new to the lathe game, in that I just bought my first lathe today. It was in a recycle shop near my house, and after checking it out carefully I went back again and bought it.

It's Japanese. (I'm in Japan. I'm not Japanese, but I speak/read Japanese having lived here for roughly 10 years.) Label on the front says "Cell Original Sound" - and I'm going to guess that is not the name of the manufacturer since it says "Side B 33 1/3 RPM" - but it has no other identifying marks on it anywhere. Google searching it took me to a photo that someone else had snapped of this unit 2 years earlier when it sat in the same shop, but was twice as much. (I paid $400 for it)

It is probably manufactured by the same person/company as the one in this video (which has been discussed on this forum before), but a different model:

I checked mine as carefully as I could before purchasing. Runs nice and smooth, and I even got the recycle shop to let me test cut onto a CD. It all looks to be 90% functioning.

It's mono. Has two inputs an "input" and a "mic in" - both are 1/4" jack inputs. IT has RCA jacks as well, but it doesn't say if these are in or out - haven't tested them yet. Also has a mono headphone jack. The 1/4" Input has a weak signal, but I imagine since it's mono, if you use the "mic in" it would be just fine. The only other problem is that the Amperage meter (I believe that's what it is) doesn't seem to work. Though to be honest, I'm not entirely sure what it's function would be on this unit. The dial next to it has a W (Watts?) and an Ohms mark on it.

The rest of it works just fine. Love the arm on this thing.

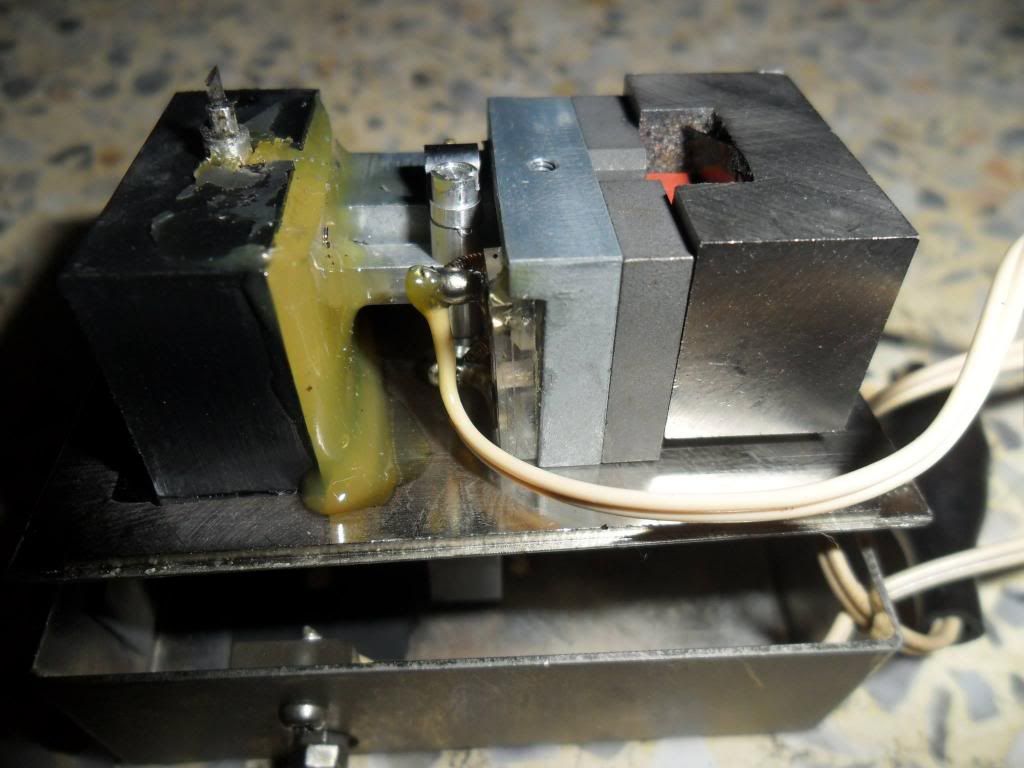

Slightly different angle:

It's built like a tank. In fact, I have no idea how I will get into it if I decide to repair the weak 1/4" input. Has no screws anywhere. Just rivets on the outside of the trunk/case that it sits in. I'll probably just stick with the Mic input for the signal in since that works very well and compensate for the line difference - but at some point in the future, if I get more serious about this, I may want to do some small modifications to it.

For making practice cuts, I have an endless source of cheap laser discs here in Japan. While they never caught on in the states, they became big here, and they're dirt cheap now, and roughly the same size as a 12" record. If I bore out their centers a little, they will take a 45 adapter. In the meantime, as long as I center them with a ruler, the spindle clamp should hold them steady. Will see how it goes once I get everything set up.

Would love advice on setting up a good signal path for this - i.e. EQs? Compression? Pre-amp? What's the way to go?

Thank you again for your consideration. Will try and post more pictures later for greater detail/documentation purposes.